When it’s time to get to work, the right heavy equipment can make all the difference on a construction site. From excavators to dump trucks, this article strips down the array of options to the most critical pieces, guides you in maintenance practices to keep them running smoothly, and helps you weigh the benefits of buying versus renting based on your project’s scale and duration.

Key Takeaways

-

A wide range of heavy machinery is vital for construction work performing diverse tasks, with safety and maintenance being crucial to prevent potential accidents and enhance the longevity of equipment.

-

The evolution of construction equipment from manual labor to mechanization and ongoing technological innovations in machinery has continuously improved efficiency and safety on construction sites.

-

Selecting the right construction equipment requires considering factors like project scope and site conditions, and the decision to rent or purchase depends on cost, usage frequency, and project duration.

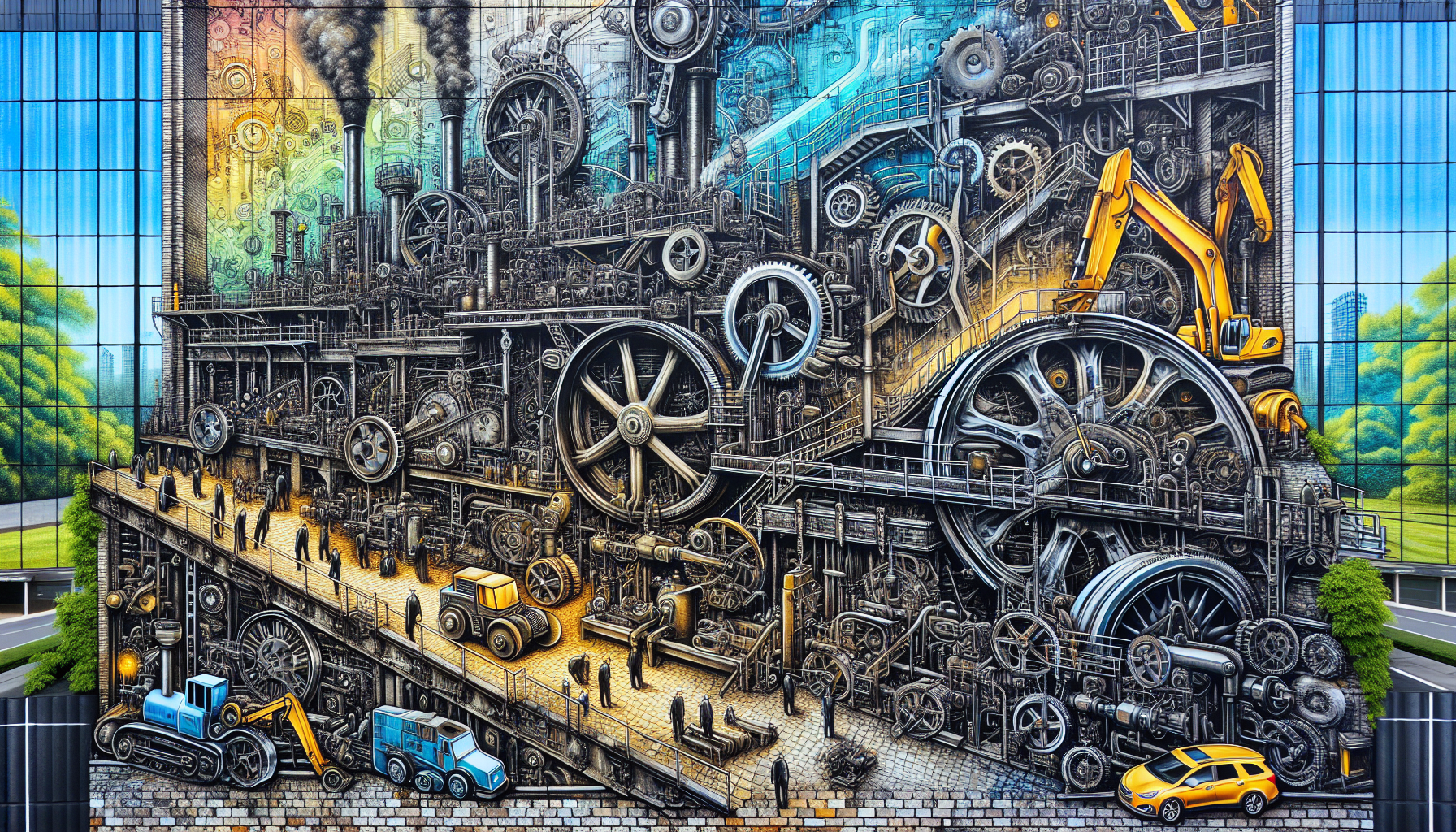

Understanding Heavy Equipment in the Construction Industry

Heavy equipment, alternatively referred to as heavy machinery, heavy trucks, or heavy hydraulics, embodies heavy-duty vehicles engineered for construction and earthmoving tasks. The term ‘heavy’ doesn’t relate to their physical weight or size, but to the heavy-duty nature of the tasks they perform. They come in various types, including:

-

Wheel loaders

-

Bulldozers

-

Excavators

-

Scrapers

-

Backhoes

-

Dump trucks

-

Graders

-

Off-road forklifts

These machines are the workhorses of the construction industry, shaping our infrastructure and built environment using various building material.

Types of Heavy Machinery Used on Job Sites

A diverse range of heavy machinery finds utilization in the construction industry, each variety catering to a particular function. Some examples include:

-

Excavators: used for tasks such as excavation, heavy lifting, demolition, and material handling.

-

Backhoes: versatile machines that can perform earthmoving, demolition, excavation, and material handling by attaching diverse tools.

-

Chain trenchers: employed for more challenging terrain, with an adjustable boom for cutting trenches of various sizes.

-

Motor graders: pivotal for road construction, creating precise level surfaces.

The right equipment is chosen based on the specific requirements of the job site.

Importance of Equipment Safety and Maintenance

Maintenance and safety emerge as paramount facets in the realm of heavy machinery. Regular maintenance and inspections help detect and repair minor flaws, preventing larger issues and potential equipment failure. It also enhances employee safety by uncovering and fixing faults that could lead to accidents.

Proper maintenance not only prevents equipment breakdowns but also supports a company’s productivity and profitability. It can significantly reduce operating costs, extend the lifespan of heavy equipment, and ensure optimal performance in challenging environments.

The Evolution of Building Construction Equipment

Since the advent of the second Industrial Revolution in the late 1800s, which signified the onset of mechanization, building construction equipment has undergone immense evolution. From the introduction of bucket wheel excavators in the 1920s to the current advancements in construction equipment technology, such as self-healing concrete and predictive maintenance, the industry has continuously evolved to enhance efficiency and safety.

From Manual Labor to Mechanization

The transition from manual labor to mechanized construction was a game-changer. This shift began with the introduction of steam and gas-powered tractors in the late 19th century. Benjamin Holt’s steam engine tractor in 1890 and John Froelich’s gas-powered tractor in 1892 laid the groundwork for subsequent advancements.

The transition gained significant momentum in 1906 with Holt’s invention of the gas-powered track-type tractor, transforming the construction industry.

Innovations in Aerial Work Platforms

In the realm of construction, innovation has been a crucial driver for aerial work platform development, including the advancement of boom lifts and mobile elevating work platforms. The Bronto S341HLA aerial platform, for instance, stands as North America’s tallest truck-mounted aerial platform, offering wireless remote control for enhanced safety and convenience. Versalift’s VST-52-MHI introduces unique safety features—Electroguard and TruGuard—that provide comprehensive dielectric isolation. These innovations underscore the continuous strive to enhance safety and productivity in construction work.

Selecting the Right Equipment for Your Construction Project

Choosing the appropriate equipment for a construction project holds paramount importance. It involves considering several factors including:

-

The project scope

-

Site conditions

-

Equipment size

-

Need for specialty equipment

-

Attachment requirements

These factors influence efficiency and suitability for the job.

It also involves decision-making regarding:

-

Whether to rent or purchase construction equipment

-

Frequency of equipment usage

-

Length of the project

-

Overall cost considerations

Criteria for Equipment Selection

The project scope significantly influences equipment selection, necessitating either versatile multi-purpose machines or a combination of specialized models depending on the tasks required. Apart from this, the choice of construction equipment must account for the size and maneuverability of the machinery, particularly when the job site has limited space.

The availability of specialty equipment or the ability to attach different tools to existing machinery greatly expands the range of tasks that can be accomplished while managing costs and space.

Common Rental vs. Purchase Decisions

The decision between renting and purchasing heavy equipment must take into account a company’s financial capacity to absorb purchase costs versus ongoing rental expenses. Renting equipment may offer a cost benefit over purchasing for short-term usage, negating concerns about storage and long-term maintenance.

On the other hand, acquiring equipment involves a major capital investment appropriate for machinery expected to be used extensively across multiple projects. Therefore, understanding and evaluating these factors are crucial to make an informed financial decision.

Heavy Equipment and Material Transportation

In the construction industry, the transportation of heavy equipment and materials presents a formidable challenge. This process requires careful route planning to circumvent complications posed by narrow roads, low bridges, and tunnels when dealing with oversized loads. Special transport considerations are necessary for certain heavy equipment due to their exceptional dimensions or specific handling needs.

Efficient scheduling of transport is imperative to align with construction timelines and maintain project client satisfaction.

Transport Solutions for Heavy Loads

Depending on the nature of the goods, diverse approaches are available for transporting heavy loads. Flatbed trucks, for instance, are equipped with an open cargo carrier that simplifies the process of loading and unloading bulky items like pipes, wood, and crates.

On the other hand, trailer trucks are typically designed for long-haul logistics, making them suitable for transporting large volumes of goods that are stackable.

Ensuring Safe Transit of Construction Equipment

Ensuring the safe transit of construction equipment is a top priority. This involves:

-

Properly securing heavy equipment during transportation with the correct restraints, bracing, and bolting to prevent damage, accidents, and to avoid citations and fines.

-

Securement systems should comply with DOT regulations, capable of withstanding forces in multiple directions relative to the cargo’s weight.

-

Use minimum four tie-downs that meet appropriate Working Load Limits.

Multiple checks of the following components before departure, as well as periodic stops to inspect them, are essential to ensure ongoing safety throughout the journey:

-

Chains

-

Securement points

-

Hitches

-

Tires

Maintenance Work: Extending the Life of Heavy Equipment

In the domain of construction work, prolonging the lifespan of heavy equipment is a critical element. This can be achieved through diligent maintenance work. Some best practices in heavy equipment maintenance include:

-

Adherence to manufacturer recommendations

-

Keeping detailed records

-

Understanding warranty requirements

-

Maintaining an inventory of parts

-

Training maintenance crews

-

Monitoring maintenance costs

By following these practices, you can ensure that your heavy equipment lasts longer and operates at its best.

The ready availability and close proximity of spare parts for the heavy equipment can considerably influence both the efficiency of the project and adherence to budgetary constraints.

Scheduled Maintenance Routines

Scheduled maintenance routines play a vital role in extending the life of heavy equipment. Maintenance management software aids in scheduling and managing inspection and maintenance tasks, supplemented by manufacturer maintenance schedules and the use of operating hours for planning preventive maintenance.

Routine maintenance tasks include basic engine services every 250 to 500 hours and more thorough inspections and replacements for components such as cabin air filters, coolant filters, and hydraulic oils at longer service intervals. Tracking service efforts through accurate maintenance records ensures adherence to schedules and supports future transactions by maintaining detailed histories of maintenance and major issues.

Handling Repairs and Parts Replacement

Handling repairs and parts replacement is an inherent part of heavy machinery maintenance work. Whether it’s Original Equipment Manufacturer (OEM) parts or aftermarket parts, each has its own advantages and disadvantages. Here are the different types of parts you can consider:

-

New parts: These come with a warranty, promising longevity but are pricier.

-

Used parts: These save costs but have wear and may lack warranty.

-

Rebuilt parts: These replace only worn components and might have limited warranty.

-

Exchange parts: These provide a balance between cost and quality.

Consider your budget and specific needs when choosing the type of parts for your heavy machinery maintenance.

Understanding these different options can help in making informed decisions that can extend the life of your equipment while keeping costs in check.

The Role of Heavy Equipment in Specialized Construction Tasks

Owing to the unique demands of the job, specialized construction tasks frequently necessitate particular heavy machinery. For instance, chain and wheeled trenchers are specialized heavy equipment critical for digging trenches for pipelines, cables, or drainage, chosen based on the project’s specific soil conditions and trenching requirements.

The successful use of specialized equipment such as trenchers depends not only on the machinery’s capabilities but also on having an adequately trained team to operate it.

Excavation and Digging

In the world of excavation and digging, trenchers play a pivotal role. These machines are designed to easily and efficiently dig through both hard and soft soils, making them ideal for creating trenches for pipelines, cables, or drainage systems.

The choice between chain and wheeled trenchers depends on the specific soil conditions and trenching requirements of the project. With the right machinery and a well-trained team, excavation and digging tasks can be carried out safely and efficiently.

High-Rise Construction Challenges

When it comes to high-rise construction, the challenges multiply. These structures require specific equipment like tower cranes which are essential for the construction of tall buildings due to their ability to hoist heavy materials like concrete blocks and steel trusses to great heights.

Hammerhead cranes are favored in high-rise construction for their ability to move loads horizontally without changing their level. Luffing tower cranes, adept at lifting heavier loads and operating in crowded areas, are another staple in high-rise construction. These specialized machines enable builders to overcome the unique challenges of high-rise construction.

Heavy Equipment Manufacturers and Industry Standards

The heavy equipment manufacturing industry is helmed by leading companies that establish standards for quality and innovation. These manufacturers not only produce top-of-the-line equipment but also adhere to various industry standards, including ISO certifications for quality management systems. They also comply with engineering and safety standards such as those issued by OSHA to ensure the safety and reliability of machinery.

Top Manufacturers in the Construction Equipment Sector

The construction equipment sector boasts of several top manufacturers who have made a mark in the industry. Some of the notable players in the sector include:

-

Caterpillar (also known as CAT), the world’s largest construction equipment supplier and manufacturer

-

Komatsu, the largest Japanese construction equipment manufacturer

-

Liebherr, a German company

-

John Deere, which manufactures equipment for agriculture and construction

These companies have established themselves as leaders in the construction equipment industry.

These manufacturers are recognized for their significant revenue contributions and the quality of construction equipment they provide to the global market.

Adherence to Engineering and Safety Standards

Adherence to engineering and safety standards is crucial in the manufacturing of heavy equipment. Safety standards for industrial robots, including design and protective measures, are articulated in international standards such as ISO 10218-1&2 and adopted with added emphasis on risk assessments in North American regulation RIA 15.06-15.

Non-compliance with these standards can result in legal actions and penalties, emphasizing the critical nature of adhering to these regulations to avoid accidents and legal consequences.

Enhancing Efficiency with Modern Construction Technologies

The advent of modern construction technologies has brought about a revolution in the industry, resulting in improved efficiency. These technologies include:

-

Equipment tracking software

-

IoT devices

-

Cloud-based platforms

-

Artificial intelligence

-

Machine learning

-

Drones

-

Virtual and augmented reality technologies

-

Wearable safety devices

GPS and Machine Control Systems

GPS technology has played a significant role in enhancing construction management by providing a data-driven approach, ensuring the safety of equipment, and increasing overall productivity among workers and site managers.

The integration of GPS in construction equipment offers several benefits, including:

-

Precise elevation data for site surveying

-

Mapping capabilities for accurate project planning

-

Grading capabilities to ensure level surfaces

-

Expedited processes and reduced labor costs

Automation and Remote Operation

The advent of automation and remote operation has significantly transformed construction work. Automation in construction aims to:

-

Increase machine autonomy

-

Reduce jobsite injuries

-

Speed up activity completion

-

Enforce quality control

Automated machinery such as cranes, excavators, and bulldozers can be controlled remotely, which enhances operational efficiency on construction sites.

Summary

In conclusion, heavy equipment plays a vital role in the construction industry, from building infrastructure to shaping our built environment. The evolution of this machinery, from the era of mechanization to the present day, is a testament to human innovation and ingenuity. With the advent of modern technologies, the industry is set to witness even more significant transformations. As we continue to build and grow, heavy equipment will undoubtedly remain at the heart of construction, making our lives better, one project at a time.

Frequently Asked Questions

What are the three types of aerial lifts?

The three types of aerial lifts are scissor lifts, boom lifts, and telehandlers. Each type serves a unique purpose and is best suited for different jobs and environments.

What is the best brand of heavy equipment?

Caterpillar is often considered the best brand of heavy equipment due to its reputation as the world's largest construction equipment supplier and manufacturer.

What is the most used heavy equipment?

The most used heavy equipment includes wheel loaders, excavators, backhoes, bulldozers, graders, skid steers, articulated trucks, and compact track loaders. These are popular on construction sites for various tasks.

What is classified as heavy equipment?

Heavy equipment includes machinery that can handle heavy-duty work, such as earthwork.

Which are heavy equipment?

Heavy equipment includes articulated trucks, asphalt pavers, backhoe loaders, boom lifts, cold planers, compactors, and dozers. These are commonly used in construction and other industries.