Struggling with JLG lift downtimes? Our focused guide on JLG lift parts and services zeroes in on keeping your lifts in action. This includes key components for top performance, how to find the right parts, and the service solutions that ensure quick, effective maintenance. Dive in to maintain your lift’s efficiency and safety without hassle.

Key Takeaways

-

JLG lift components like ride control systems and hydraulic accumulators are crucial for optimal performance, enhancing operator confidence and job site efficiency through increased stability and shock mitigation.

-

With over 200,000 SKUs, JLG offers a comprehensive range of replacement parts for diverse brands and their global distribution network ensures these parts and services, including remanufactured options, are readily accessible for efficient fleet maintenance.

-

JLG Industries, Inc. emphasizes safety and innovation, evidenced by their extensive product lineup including SkyGuard technology, an Augmented Reality (AR) App for equipment management, and a variety of customizable accessories to meet unique job site needs.

Essential JLG Lift Components for Optimal Performance

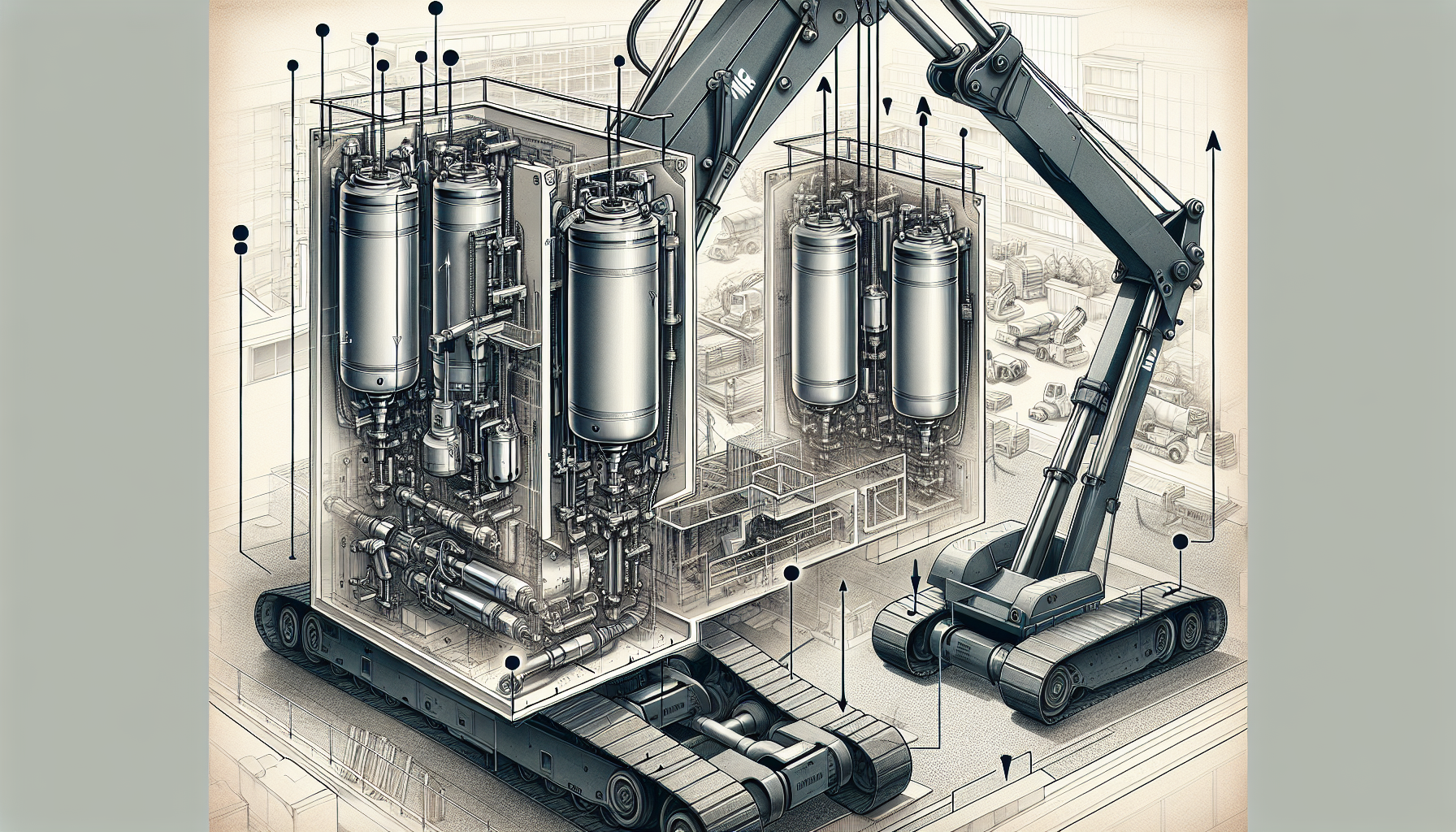

Two components are vital to the optimal performance of JLG lift equipment - ride control systems and hydraulic accumulators. The ride control system acts as a boom suspension system, allowing the boom and load to absorb energy from uneven terrain. This not only enhances operator confidence but also boosts productivity. Such systems empower operators to move loads with increased stability under various conditions, thus raising job site efficiency and ensuring safety.

But how do these ride control systems work so effectively? The answer lies in the hydraulic accumulators. These components store energy and mitigate shock as part of the ride control system. They are essential for mobile equipment managing high force loads.

JLG Replacement Parts: Keeping Your Fleet Ready

JLG replacement parts play a vital role in maintaining the readiness of your aerial lift equipment fleet. MaxQuip by JLG, for instance, supplies over 26,000 SKUs in more than 65 product categories. This caters to a broad range of brands and mixed-fleet needs, ensuring that your fleet is always ready for action.

You might wonder, can older JLG equipment be maintained without breaking the bank? Absolutely! Remanufactured parts are available as a cost-effective solution for older JLG equipment. They meet OEM specifications with warranty assurance, thus maintaining the readiness of your fleet.

One of the best aspects of JLG replacement parts is their accessibility. Thanks to a global distribution network, these parts are readily accessible, supporting various regional service centers and distributors. So, you can rely on JLG replacement parts for fast and efficient fleet maintenance.

Service Solutions for JLG Equipment

JLG doesn’t just stop at providing quality lift parts; they also offer comprehensive on-site services. Factory-trained technicians from their authorized service providers, like Brown's Heavy Equipment (BHE), perform the following services for different types of aerial lift equipment including boom lifts, scissor lifts, and telehandlers:

-

Inspections

-

Maintenance

-

Troubleshooting

-

Repair

-

Overhaul

In case of emergencies, you can rely on BHE’s mobile service. Technicians can quickly respond and perform on-site repairs using fully equipped service vehicles, ensuring that your equipment is up and running in no time.

BHE also provides remanufactured parts through JLG Reman for maintaining and repairing older JLG equipment. These parts come with a one-year warranty, making it a cost-effective solution.

Alongside, the JLG Service Provider Network offers dependable repairs, warranty services, regular maintenance, and ready access to parts for a variety of equipment brands and models.

How to Find the Right JLG Lift Part

Securing the right JLG lift part is just as important as ensuring its quality. JLG lift parts are designed as the exact original equipment fit for JLG aerial scissor or boom lifts. They offer three lines of parts - JLG Genuine, MaxQuip, and JLG Reman - to suit different requirements and budgets. In addition to JLG, it’s essential to consider other options like skyjack lift parts for your equipment needs.

JLG’s Online Express platform includes tools such as 3-D Schematics and interactive parts manuals. These facilitate the precise identification of the required parts by entering the machine’s serial number. The platform also provides a comprehensive overview for JLG products by serial number, aiding in the accurate selection of appropriate parts.

If you prefer shopping online, BHE Lift Parts online store is there for you. You can find and order JLG parts efficiently by searching with the part number or description. And if you need help, BHE’s customer support team is available for personalized assistance in finding parts quickly via online chat, phone, or email support.

Maximizing Uptime with Authentic JLG Parts

Optimal productivity and performance can be achieved by using genuine JLG parts over aftermarket alternatives. These parts are carefully selected and designed for JLG equipment, ensuring they meet the exact specifications needed for optimal operation.

Genuine JLG parts:

-

are factory-approved and rigorously tested to meet original specifications by JLG engineers

-

come with a six-month warranty

-

contribute to maintaining the equipment’s resale value.

To ensure equipment uptime, JLG provides a network of service centers that offer maintenance and repairs with original equipment manufacturer (OEM) parts and technical support. They offer three lines of replacement parts, including Genuine parts, MaxQuip for mixed-fleet repairs, and Reman remanufactured parts, ensuring a wide range of options to maintain equipment uptime.

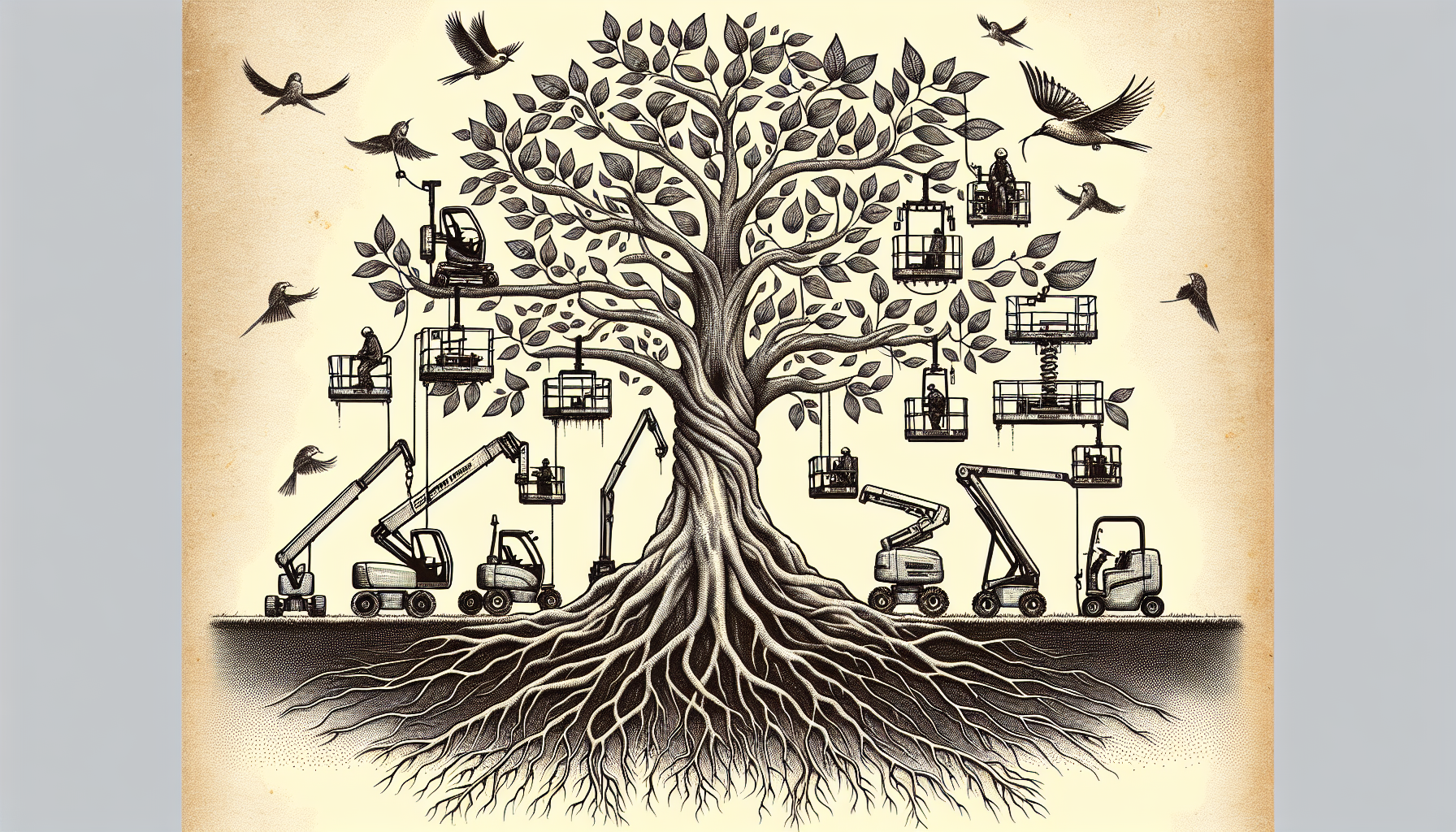

The Role of JLG in the Aerial Lift Industry

JLG Industries, Inc. has been a major player in the aerial lift industry since its inception in 1969. From creating its original aerial work platform in 1970 to becoming a subsidiary of Oshkosh Corporation in 2006, JLG has come a long way. Today, it has diverse manufacturing facilities across several countries and provides services globally.

JLG’s expansive product lineup includes various types of aerial work platforms, such as skyjack lifts, along with SkyGuard technology. This technology enhances safety by stopping functions and reversing most of them when activated, a first-of-its-kind feature in the industry. The brand’s reach and capabilities were significantly broadened with the acquisition of SkyTrak and Lull in 2003.

JLG works closely with its customers, including sectors like aviation, entertainment, and military, to engineer bespoke lifts that cater to specific industry requirements.

JLG's Commitment to Safety and Innovation

JLG’s commitment to safety and innovation is evident in every aspect of their operations. JLG designs their innovations with a focus on people, aiming to create solutions that not only protect but also elevate and empower customers in their work environments.

One such innovation is the Augmented Reality (AR) App, which enhances project planning and onsite equipment management. It offers:

-

Machine and accessory visualization

-

Decal view with translation

-

Control operation guidance

-

An annual inspection assistant

To enhance the safety features of their machines, JLG has implemented a high visibility seatbelt and operator presence functionality for JLG Telehandlers.

Furthermore, they introduced a multi-reverse camera system on SkyTrak Telehandlers to improve safety during reverse operations. Their innovative Load Stability Indication System (LSI) aids operators in maintaining the forward load capacity of telehandlers, further cementing JLG’s commitment to safety through technology.

Custom Solutions for Unique Challenges

Recognizing the uniqueness of each job site and operational challenge, JLG offers a variety of accessories to boost safety and efficiency. These include:

-

Bolt-on fall arrest systems

-

Platform mesh

-

QuikAccess collapsible rails

-

Pipe racks

-

Tool trays

These accessories, known for their durability, can be tailored to manage specific job site requirements and are easy to obtain at the shop.

For projects with unique needs, JLG is capable of manufacturing one-off custom parts and accessories, even for specialized equipment like a cat. They focus on meeting specific operational challenges with a minimum of compromise, ensuring their brand remains reliable without sacrificing safety or performance.

The MaxQuip line by JLG offers:

-

Over 26,000 SKUs for various lift brands

-

Accommodating a broad range of needs for managing a mixed fleet of equipment with high-quality, authentic parts

-

Customized equipment modification services enabling the tailoring of aerial work platforms to cater to unique work environment conditions and customer-specific requirements.

Summary

In a nutshell, JLG lift parts and services play a crucial role in maintaining the optimal performance of your aerial lift equipment. Whether it’s their ride control systems, hydraulic accumulators, replacement parts, or bespoke solutions, JLG’s commitment to safety, innovation, and customer satisfaction is clearly evident. They not only provide top-quality products but also ensure that their customers can find and order the right part with ease. So, when it comes to aerial lift equipment maintenance, JLG is indeed a brand you can trust.

Frequently Asked Questions

What is the maintenance schedule for a Genie lift?

Make sure to perform one-time maintenance procedures at 50 and 150 hour intervals, as well as quarterly and annual maintenance procedures to ensure safe operation and machine performance.

Is a JLG an aerial lift?

Yes, a JLG is considered an aerial lift, known for its reliability and performance in the construction and maintenance industry.

What are the manuals that are required to be stored on all JLG telehandlers?

You need to store a copy of the Operation and Safety Manual, AEM Safety Manual (ANSI markets only), and ANSI Manual of Responsibilities (ANSI market MEWPs only) in the weather resistant storage container of the MEWP or in the telehandler cab manual holder.

Who makes JLG boom lifts?

JLG boom lifts are manufactured by JLG, a company headquartered in McConnellsburg, Pennsylvania and a subsidiary of Oshkosh Corporation. This American industrial company specializes in designing and building specialty trucks, military vehicles, and access equipment.